3d Bioprinting can help organ transplant

Thu 13 Apr 2017, 10:24:01

3D bioprinting is essentially technology that is recently gaining steam in the global markets. It’s also known as “additive manufacturing”.

You would’ve seen in the movie terminator where a machine man from the future arrives and any wound inflicted on it gets healed automatically. Or several ones from “game of thrones” where similar things happen, but for human flesh. Now, what was fiction is going to get real with this amazing technology called 3D printing.

3D printing is essentially technology that is recently gaining steam in the global markets. It’s also known as “additive manufacturing”. The emergence of 3D printing has been catalysed by advances in 3D modeling technology, like its easy availability and low cost. Models can be created of any object that one would like to get printed. This model is then broken down into minute layers, and the layer is printed one on top of the other so that they fuse together and a solid product is created. 3D printing has been around for a long time. It’s only recently that the cost of materials and machine has decreased considerably and is now almost a consumer product for low resolution printing. 3D printing today has applications in multiple industries. For example, it is being used in traditional manufacturing for prototyping and new component development. It can also be used for making moulds. It is used in the automobile industry to print exciting concept cars that can be printed as a single piece.

One of the most exciting applications of 3D printing though is in the printing of biological organs. It’s a no brainer to appreciate that there is a huge shortage of kidneys available for transplantation, all over the world. Around 10% of the world population suffers from kidney disease. Most of the time, the only alternative available to them is to depend on regular dialysis. Now this is a complicated procedure in which all the blood is removed filtered and then pumped in again. This is painful, mentally degrading and expensive too! With the new 3D bio printing technology researchers are making strong progress in developing artificial organs. The 3D bioprinting process involves three steps:

Modeling

In the modeling process, organs that need to be printed are scanned using

advanced Computer tomography tools. Detailed models are made of organ including, provisions for blood vessels inside of the organ. This model can be sliced and diced at any level and it’ll still hold true to the original

advanced Computer tomography tools. Detailed models are made of organ including, provisions for blood vessels inside of the organ. This model can be sliced and diced at any level and it’ll still hold true to the original

Printing

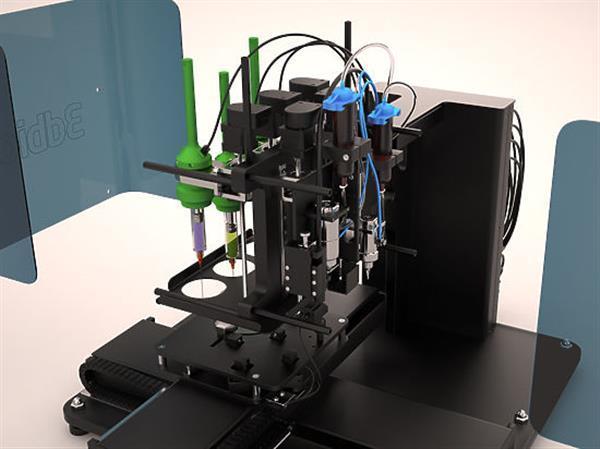

The next important step is the printing of the organ. Here the cells of specific organ, that we’re looking to print are collected. At the same time, material for the structure that gives stability to the printing process is also collected. These are typically going to be collagen and nutrients that get dissolved once the printing is complete and solidifies. The printing happens in layers by a 3D printing machine which is typically a very advanced version of your office inkjet printer. It adds layer on top of layer in a slow and gradual process. Once a layer is printed, the cells fuse together mimicking the natural biological process of embryonic cellular fusion.

Post processing:

The post processing happens in a bioreactor. The objective here is to create some stability and growth for the organ that has been created. This includes supplying nutrients for cellular growth, creating the right physiological environment for tissue maturation and doing some mechanical and biological testing to ensure the organ is working right.

Some body parts like the kidney, liver and pancreas which have complex physiological functions are a bit further away from being artificially created, versus other organs like simple skin tissue, parts of the outer ear, bladder etc.

With assistance from 3D bio printing, you can have machines that work directly on skin abrasions, patiently adding layer upon layer of fresh tissue so your wound heals gracefully without leaving any noticeable scars. You can also have pharmaceutical units like tablets printed in perfect proportions as suits your requirements versus printing the same dosage units for everyone. There have also been a lot of advances in 3D printing in the prosthetics area, where we’re hitting this important milestone where the prosthetic that has been printed for you could have better material strength and durability than the original organ you’ve been born with. That’s definitely making big steps towards creating the age of the cyborg!

No Comments For This Post, Be first to write a Comment.

Most viewed from Health

AIMIM News

Latest Urdu News

Most Viewed

May 26, 2020

Do you think Canada-India relations will improve under New PM Mark Carney?

Latest Videos View All

Like Us

Home

About Us

Advertise With Us

All Polls

Epaper Archives

Privacy Policy

Contact Us

Download Etemaad App

© 2025 Etemaad Daily News, All Rights Reserved.