ISRO Successfully Tests New Liquid Rocket Engine In Tamil Nadu

Mon 13 May 2024, 10:42:27

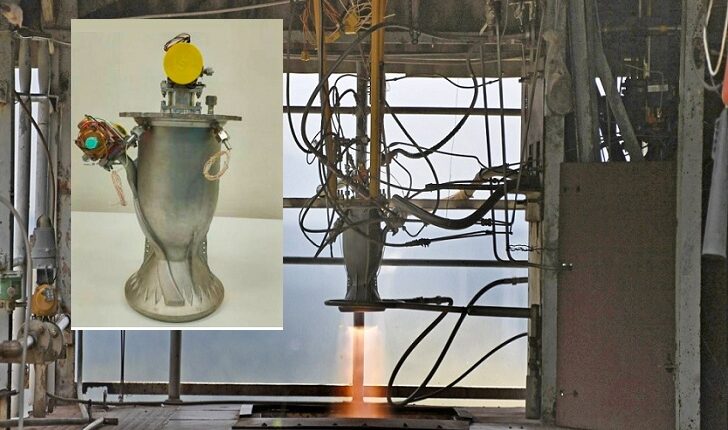

The Indian Space Research Organisation, ISRO successfully tested the new liquid rocket engine manufactured through Additive Manufacturing technology. The test was successfully carried out on May 9th at ISRO Propulsion Complex in Mahendragiri in Tamilnadu.

This new redesigned PS4 engine has brought down the number of parts from 14 to a single piece and eliminated 19 weld joints. This will significantly save on the raw material usage per engine, reduce metal powder from 565 kgs to 13.7 kgs and reduce the production time by 60

percent.

percent.

This new redesigned engine will be used for the fourth stage of PSLV launch vehicle and also in the Reaction Control System of the First Stage in PSLV. ISRO is planning to induct this PS4 engine into the regular PSLV program. Additive Manufacturing technology means 3D printing of PS4 engines. The Private partner Wipro 3D joined hands with ISRO to successfully carry out the hot testing of the 3D printed PS4 engine. This will usher in a new era of advanced 3D manufacturing technique of India’s space programme.

No Comments For This Post, Be first to write a Comment.

Most viewed from National

Most viewed from World

AIMIM News

Asaduddin Owaisi questions PM Modi's China policy

Jan 08, 2025

Owaisi slams UP over police post near Sambhal mosque

Dec 31, 2024

Owaisi hails SC order on Places of Worship Act

Dec 13, 2024

AAP Corporator Tahir Hussain joins AIMIM party

Dec 11, 2024

Latest Urdu News

Most Viewed

May 26, 2020

Which political party will win the Delhi Assembly polls to be held on Feb 5?

Latest Videos View All

Like Us

Home

About Us

Advertise With Us

All Polls

Epaper Archives

Privacy Policy

Contact Us

Download Etemaad App

© 2025 Etemaad Daily News, All Rights Reserved.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)